A general certainty of time is the innovation and development of new technology. As demands for higher efficiency rise, manufactures must test new ideas to surpass previously accepted standards and create new avenues of possibility. Within the performance fuel system industry, Injector Dynamics represents the leading edge of that progress.

Focusing on constructing the absolute best fuel injectors available, Injector Dynamics also provides it's customers with supporting testing data and technology that is unmatched by their competitors.

Focusing on constructing the absolute best fuel injectors available, Injector Dynamics also provides it's customers with supporting testing data and technology that is unmatched by their competitors.

ID's philosophy of a fuel injector being a 'dynamic' device opens new perspective on how the units should be designed and tested. By considering the actual operating environment and using the intended application fuel type, dynamic characterization testing can be accurately conducted. Utilizing laboratory grade equipment to perform these dynamic tests, Injector Dynamics systematically eliminates undesirable variances by carefully selecting matched sets of injectors. Measuring performance throughout the pulse-width range, these high impedance matched sets produce previously unseen cylinder consistency resulting in more efficient, more powerful, & easier to tune engines. The final 'dialed in' product is head and shoulders above other competitor units using similar injector outlines but are no comparison in performance. If your fuel injectors are not balanced properly, you will get cylinder variations, this is one of the main reasons we only sell, and tune with these injectors.

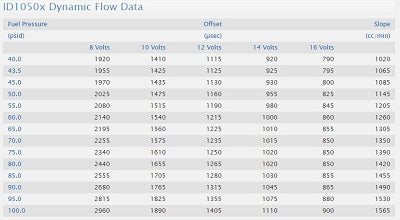

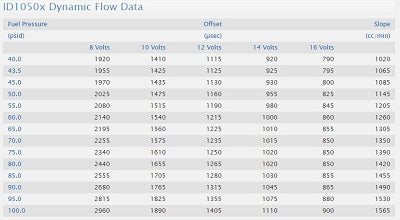

Proper injector data is CRITICAL to tuning with modern fuel injection systems. Modern ecus, like the Adaptronic Modular units require proper injector data as the basis for determining how much fuel to deliver to the engine. If you don't have this data correct, you will never get a proper tune under all running conditions.

The ID1050xis the evolution of the ID1000( now obsolete along with the ID725, ID825 & ID2000). These are the latest addition to the X-Series injectors. It is the most recent offering from the partnership of Injector Dynamics and Bosch Motorsport, and is the result of lessons learned during development of the ID1300x, and ID1700x.

Like the ID1300x and ID1700x, the ID1050x is not a modified production component. It is a built to spec motorsport injector, offering optimization of critical operating parameters important to you, the motorsport tuner.

Compared to the original ID1000, the ID1050x offers numerous improvements, and is sure to become the new reference.

- Corrosion resistant internals make it compatible with all known fuels, capable of extended service life with corrosive fuels.

- Compact body allows fitment in 200+ applications, including current and future engines utilizing short body injectors.

- Improved internal flow path increases output by 5% without sacrificing low flow performance.

- Stronger magnetic circuit offers stable operation up to 10 bar.

- Replaceable inlet filter extends service life.

The

ID1300x is an

all new injector for 2017, designed in partnership with Bosch Motorsport. This collaboration has given us the ability to design a high flow injector with characteristics specific to the needs of the motorsport tuner. The ID1300x² was designed with alternative fuels in mind, and is the only performance injector available with

all stainless internals. It is compatible with all known fuels, and will stand up to the corrosive nature of alcohol better than any injector on the market. While the

ID1300xwas designed with an eye towards ethanol fueled engines, we have accounted for the occasional need to convert back to gasoline. The ID1300x has a minimum fuel mass compatible with gasoline use, and will provide exceptional idle and cruise behavior under these conditions. In addition to its multi-fuel capabilities, the compact body of the ID1300x allows fitment in 200+ applications, making it the most versatile injector in our lineup.

The

ID1700x is the most recent offering from the partnership of Injector Dynamics and Bosch Motorsport. The

ID1700xwas designed to fill the gap between the ID1300x and the ID2000, and like the ID1300x, it features corrosion resistant internals making it compatible with all known automotive fuels.A unique magnetic circuit, resulting from a lengthy development program, makes the

ID1700x immune to voltage and pressure sensitivity problems that plague other high impedance high flow injectors. The ID1700x excels at high pressures typical of current automotive systems, and will perform flawlessly in these applications.

If you are the type with some experience modifying fuel systems, you are probably aware that solving the injector dimension riddle is only half the puzzle. To honestly boast 100% 'drop-in-upgrade' status, ID also provides fully terminated plug & play (PnP) adapters for your specific application. If you prefer a more DIY method, you also have the choice of loose terminals/connectors or a wired pigtail for your custom installation. All models are rated at high resistance /impedance to be easily compatible with most modern aftermarket ECU's.

Have any questions about installing ID Injectors in your setup? Want to check out each model's technical specs? Feel free to contact us, as unlike a lot of other online sellers, we have been tuning with these fuel injectors since day one.

Don't forget a proper fuel filter when setting up your fuel system either! Especially for those running alcohol based fuels.

Basic Specifications

Nominal Flow Rate – 750 l/h @ 7.5 kPa (1.1 psi) pressure drop. 1000 l/h @ 13 kPa (1.9 psi) pressure drop

Maximum Fuel Pressure – 10.0 Bar (145.0 psi)

Fuel Compatibility – Compatible With All Known Fuels

Fluid Connection – SAE -8 O-Ring Barb

Weight – 700g

Filter Efficiency

Electronic fuel injectors are built to precise dimensions, measured in microns. The smallest of particles can increase wear, or even destroy a fuel injector. Bosch provides a specification for protection of electronic fuel injectors, which is a minimum capture efficiency of 87% at 5 microns, and 100% capture efficiency at 35 microns. This means that the filter will capture at least 87% of all particles 5 microns and larger, and 100% of all particles 35 micron and larger. The filter element in the ID F750 meets that specification, and does so without undue flow restriction.

Flow Restriction vs Contaminant Load

The ID F750 is designed to hold a high level of contaminant while maintaining low restriction to flow. This is accomplished with a highly efficient filter element, designed with low pressure drop in mind. At a flow rate of 750 liters per hour, the ID F750 will hold five grams of contaminant, the equivalent of approximately one teaspoon before requiring replacement. Higher flow rates are possible, but will require more frequent filter changes, depending on the cleanliness of your fuel system.

Delta P Indicator

Delta P is short for delta pressure, which is the difference in pressure between two points. In this case, those two points are the inlet and outlet of the filter. The Delta P indicator gives a visual indication of the condition of the serviceable filter element, so that it can be replaced before it becomes a problem.

Spin on Housing With Safety Latch

The spin on filter housing features a safety latch to ensure that the housing can not spin off, should it loosen. It is easily released with one finger, and emits an audible click during assembly.

Pressure Relief and Drain

The ID F750 includes a standard Schrader valve and an o-ring sealed spin on barb which actuates the needle. This valve can be used for pressure monitoring, draining the system, or relieving pressure for filter changes.

Modular Mounting Bracket

The modular design allows for numerous mounting options, from the standard 90°, straight, and reverse 90°, to roll bar tube mount brackets, and everything in-between. Custom brackets can also be provided for application specific fitment.

Optional Pressure and Temperature Sensor Block

The plug and play pressure and temperature sensor features a Bosch Motorsport 10 bar (145 psi) pressure sensor, with integral -40 to 140°C (-40 to 284°F) temperature sensor. It installs with two screws, and adds 30 mm to the overall width. Due to its compact size, it can be added to most systems without need for re-plumbing.

Focusing on constructing the absolute best fuel injectors available, Injector Dynamics also provides it's customers with supporting testing data and technology that is unmatched by their competitors.

Focusing on constructing the absolute best fuel injectors available, Injector Dynamics also provides it's customers with supporting testing data and technology that is unmatched by their competitors.